poda ya chuma ya kabonili

Maelezo ya bidhaa

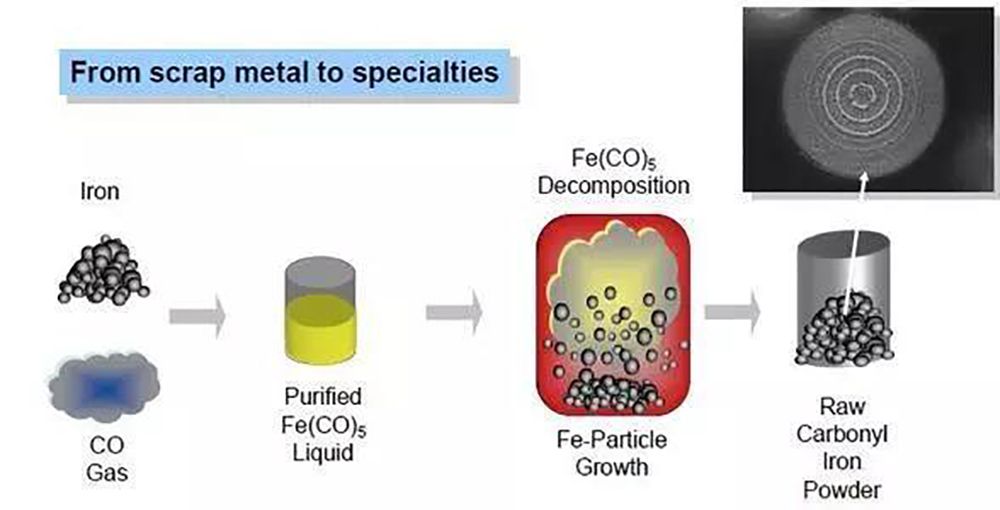

Poda ya chuma ya kaboni ni aina ya poda ya chuma-safi, ambayo ina sifa ya usafi wa juu, unyevu mzuri, mtawanyiko mzuri, shughuli za juu, sifa bora za sumakuumeme, ukandamizaji mzuri na uundaji wa sintering.Poda ya chuma ya kaboni hutumiwa sana katika kijeshi, umeme, kemikali, dawa, chakula, kilimo na nyanja zingine.Poda ya chuma ya kaboni inaweza kutayarishwa katika aina tofauti kama vile nyuzinyuzi, flake au mpira kulingana na mahitaji ili kukidhi mahitaji tofauti ya wateja.

Vipimo

| Kipengee | Muundo wa Kemikali | Mali ya Kimwili | |||||||

| Fe | C | N | O | APP.Msongamano | Gonga Uzito | Ukubwa wa Chembe ya Laser | |||

| ≥ % | ≤% | ≥ | ≥ | D10 | D50 | D90 | |||

| HR1-1 | 98 | 0.8 | 0.6 | 0.4 | 2.2 | 4 | 0.5-1.0 | ≤2.0 | 3.0-5.0 |

| HR1-2 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 3.9 | 0.6-1.5 | 2.0-3.0 | 4.5-8.0 |

| HR1-3 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 3.8 | 1.0-3.0 | 3.0-5.0 | 5.0-12.0 |

| HR1-4 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 1.5-3.5 | 5.0-6.0 | 11.5-16.5 |

| HR1-5 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 2.0-4.0 | ≥6.0 | 44915 |

| HR1-6 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 4 | 1.5-2.5 | 3.0-4.0 | 5.5-8.5 |

| HR1-7 | 98 | 0.8 | 0.7 | 0.4 | 2.5 | 4 | 2.0-3.6 | 4.0-5.0 | 7.0-11.0 |

| HR1-8 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 2.6-4.0 | 5.0-6.0 | 11.5-14.5 |

| HR2-1 | 99.5 | 0.05 | 0.01 | 0.3 | 2.5 | 3.8 | 0.58-1.5 | ≤3.0 | 4.5-8.0 |

| HR2-2 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.8 | 0.9-3.0 | 3.0-5.0 | 5.5-12.0 |

| HR2-3 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.6 | 1.5-3.0 | 5.0-8.0 | 10.0-18.0 |

| HR2-4 | 99.5 | 0.1 | 0.05 | 0.3 | 2.5 | 3.6 | 0.9-3.0 | 3.0-8.0 | 5.5-18.0 |

| HR2-5 | 99.5 | 0.4 | 0.2 | 0.3 | 2.5 | 3.6 | 0.9-3.0 | 3.0-8.0 | 5.5-18.0 |

| HR2-6 | 99.5 | 0.05 | 0.01 | 0.4 | 2.5 | 3.8 | 0.5-1.0 | ≤2.0 | 3.0-5.0 |

| HR2-7 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.8 | 1.5-3.0 | 3.0-5.0 | 5.5-11 |

| HR2-8 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.6 | 2.0-3.5 | 5.0-8.0 | 10.0-15.0 |

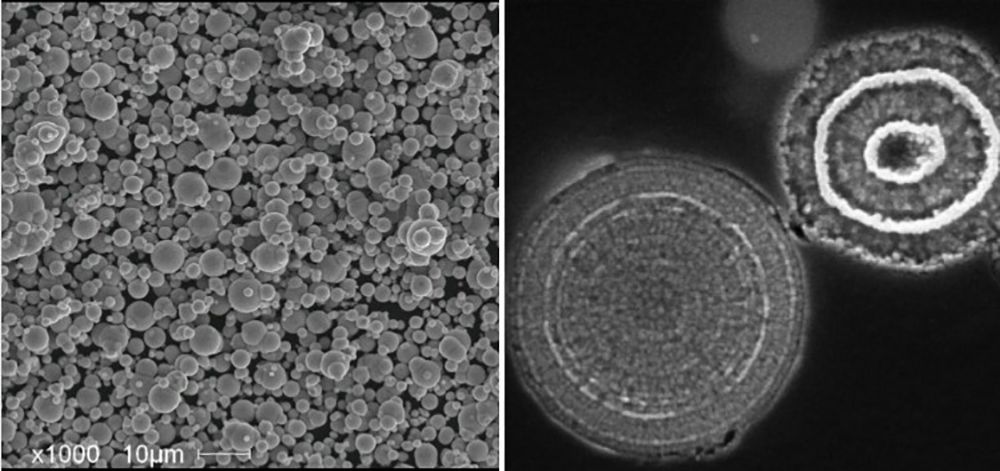

Sem

Faida

1.Usafi wa juu wa kemikali

2.Sifa bora za sumakuumeme

3.Spherical

chembe, muundo wa ngozi ya kitunguu

4.0.1-10 chembe ya msingi ya mikroni

5. High flowability, dispersibility na uthabiti

6.Hgh shughuli, compressibility na sifa bora sintering